The circular factory is not just a vision. It’s a highly interdisciplinary and challenging project that is currently being tested for washing machines at the V-ZUG headquarters, and will progressively be extended to the restof the product categories. The goal is to finalise the transition by 2040, also thanks to a self-imposed carbon tax, calculated every year in proportion to the company’s emissions and aimed at financing sustainability projects, in yet another example of circular thinking. Follow the journey of V-ZUG appliances, and discover the multiple ways in which they and their components can be repaired, refurbished, recircled,recycled, reused and repurposed.

Today, most electronic appliance manufacturers follow a linear model. By teaming up with researchers, suppliers, business and technology partners, recycling companies, and customers themselves, V-ZUG has been developing a new business model, in which appliances and their components are kept in a circular flow for as long as possible.

1 Material Selection

Making an electronic appliance requires a variety of raw materials, from metals to plastics, glass, electronics and more. V-ZUG selects them with sustainability in mind. That means reducing their quantity wherever it is possible and favouring those that either are recycled, recyclable, or have minimal environmental impact throughout their lifecycle. For example, some parts of the products are already made using recycled aluminium, CO2-reduced stainless steel, and biological alternatives to petroleum-based plastics.

2 Supply Chain

Suppliers play a key role in the implementation of a circular model. They not only provide the components that are necessary to make the products but also get back those that can potentially be reused at the end of the cycle. An example is one of V-ZUG’s suppliers, located only 30 km away from the company’s headquarters, which delivers washing machines’ base units to the factory several times a week, and takes back dismantled ones. After being shredded, they are turned into new base units, effectively closing the loop.

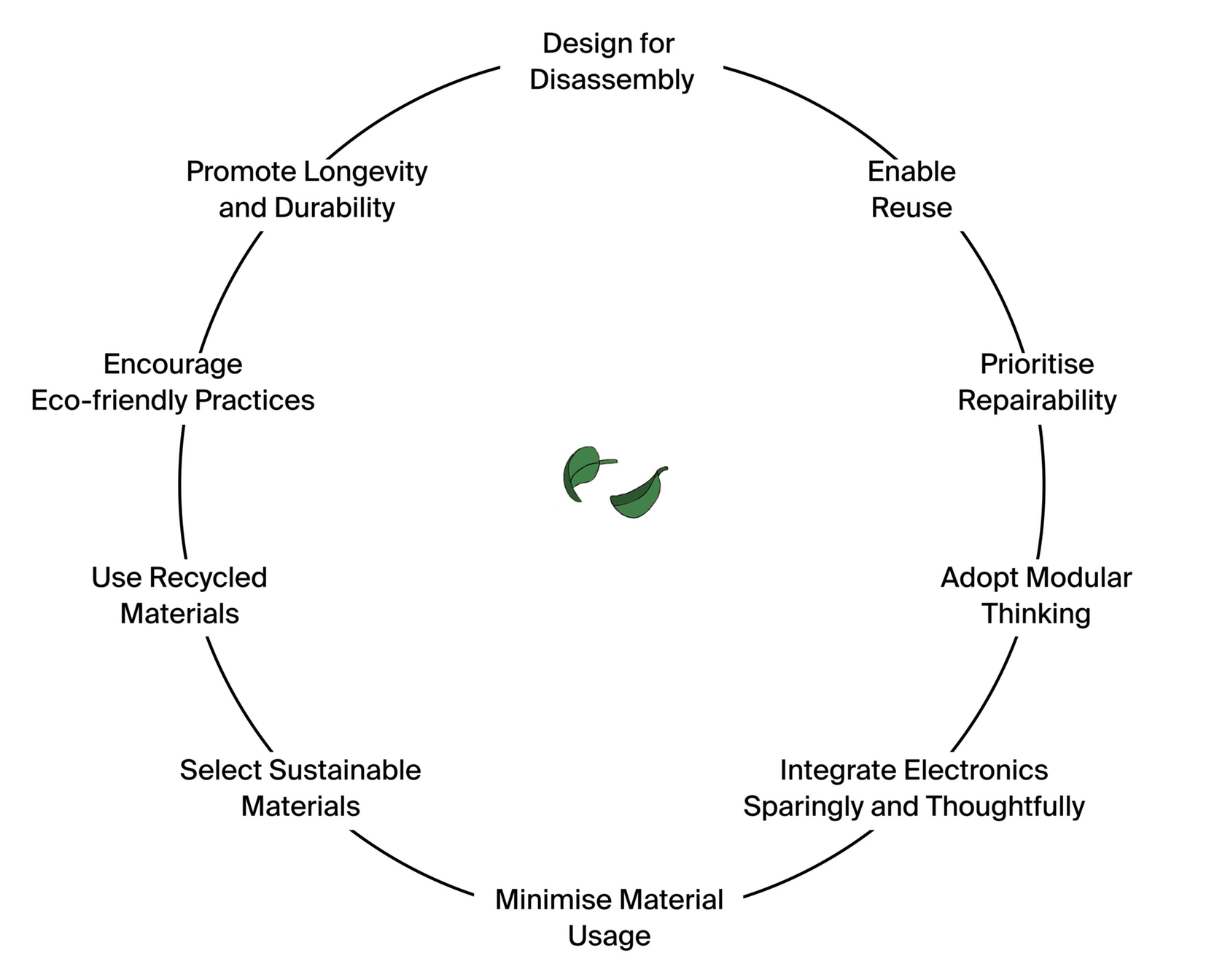

3 Design

V-ZUG’s designers play a crucial role in implementing a circular model. During product development, they take into consideration a series of factors aimed at keeping appliances and their components in use for as long as possible. For instance, they focus on repairability, opt for a timeless aesthetic, and design devices to be modular and easy to disassemble, ensuring that components can be easily reused and upgraded.

4 Production

Where and how a company produces and assembles its electronic appliances is essential in a sustainable businessmodel. V-ZUG is committed to Switzerland: over the past eight years, the company has invested CHF 300 million (USD334 million) in the production facilities in Zug and its new refrigerator production site in Sulgen. Most of its suppliers are also located within the Swiss territory, thus contributing to a sustainable business model, that benefits the company, the environment, and the local communities.

5 Sale/Offer as a Service

Today, B2B customers can not only buy V-ZUG products but also order them as a service, following a business model thatis already widespread for cars, laptops or smartphones. This means that the company commits to installing, repairing, and replacing the product, whenever needed, while retaining ownership. When the contract period is over, V-ZUG simply takes the appliance back, and reuses, recycles or reprocesses it, either in parts or as a whole.

6 Usage

Almost 70% of the environmental impact of a V-ZUG Adora V4000 washing machine is generated during its use. V-ZUG provides its customers with clear guidance and digitalfunctions, to help them operate their appliances efficiently, extend their lifespan and ultimately reduce their carbonfootprint. When issues arise that customers cannot resolve on their own, the company ensures that a technician is there to help, and that spare parts remain available for at least 15 years.

7 On-site repairs

Repairing and maintaining products plays a crucial role in extending their lifetime. V-ZUG supports its customers throughout the entire service life of their appliances, with 700 service professionals deployed worldwide. To facilitate their work, the company is developing a digital twin for every product in its system, which will display the materials contained in each appliance and how they can be reused in the future, as well as how many times its components have been repaired orreplaced.

8 Circular factory

After dismissal, washing machines are sent back to a dedicated area of the V-ZUG facilities called “the circular factory pilot.” Here, they are examined and sorted, based on whether and how they can be reused. The goal is to keep all appliances, components and parts in the cycle for as long as possible atthe highest possible quality. Only when individual parts can no longer be reused will they be transformed back into raw materials via a recycling facility.

9 Recycling

Today, many components of an electronic appliance can only be downcycled or recycled in waste incineration plants. Bringing them back into the production cycle might be a better solution. V-ZUG is already doing it with counterbalance weights in greycast iron: a recycling company located close to the company’s headquarters removes them from washing machines and sends them back to the factory, where they can be reused on eto-one. Compared to making new ones out of virgin resources, this approach reduces the environmental impact by 95%.

10 Repurposing

If a product cannot be repaired, it might get dismantled. Parts that cannot be reused or reintroduced into the production cycle will be repurposed. In the case of washing machines, used stainless steel drums have recently been turned into high-quality pieces of furniture, while glass doors have been repurposed into salad bowls.