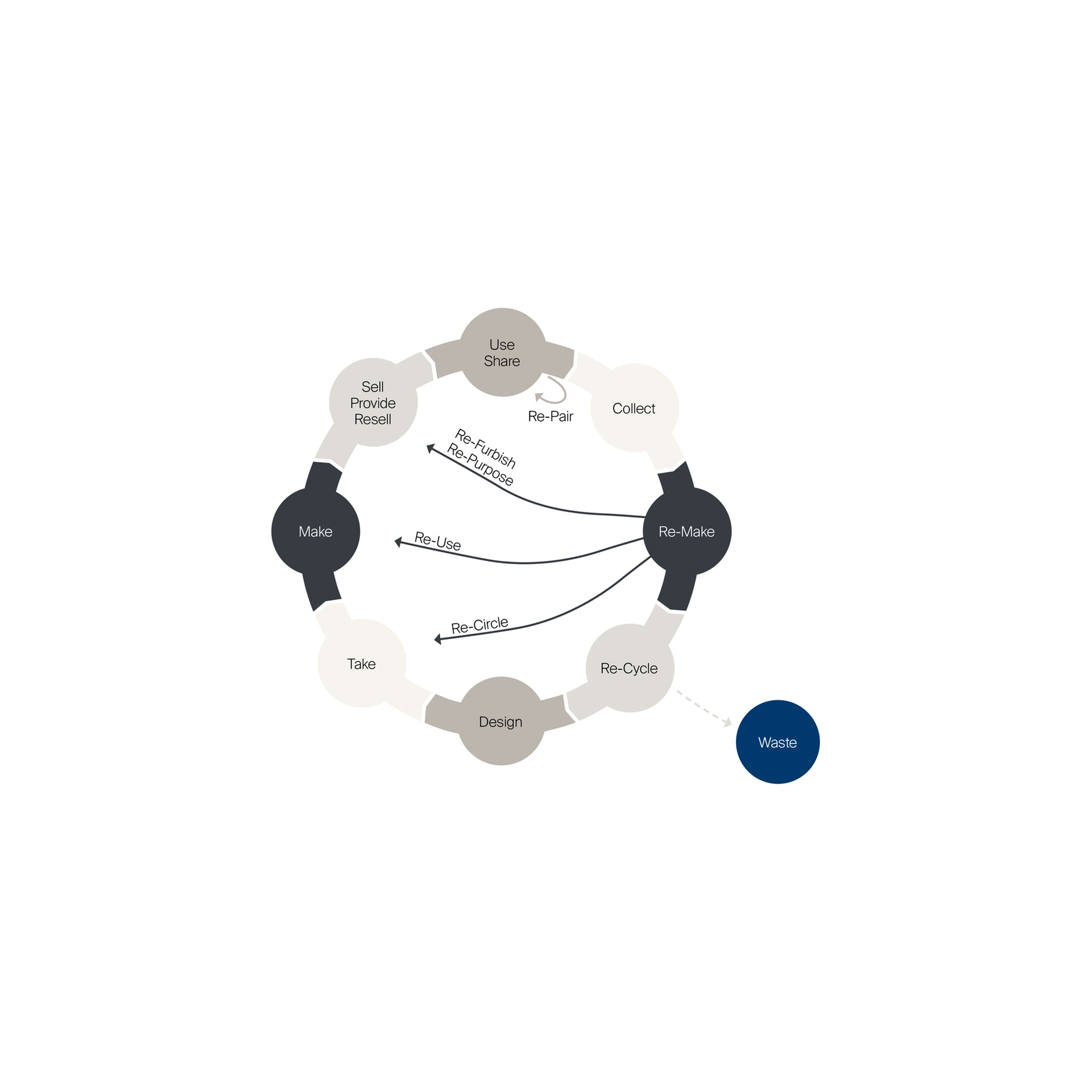

V-ZUG is consistently aligning its long-term sustainability strategy with the principles of the circular economy. Although this transformation is in its early stages, we are pursuing this path with great determination. We see the gradual introduction of the circular economy as a necessary and strategic step. It will enable us to minimise the environmental impact of our business activities in the long term and reinforce our supply chains with closed materials cycles. This helps us increase our resilience and boost our competitiveness. In Switzerland and Europe, while our soils do not contain many raw materials, quite a few raw materials are used in products. The aim is to tap into these material cycles and evolve from a successful recycling economy into a circular economy.

V-ZUG is aligning its long-term sustainability strategy with the principles of the circular economy—closing material loops, taking responsibility across the entire product life cycle, and shaping a more sustainable future through strong partnerships.

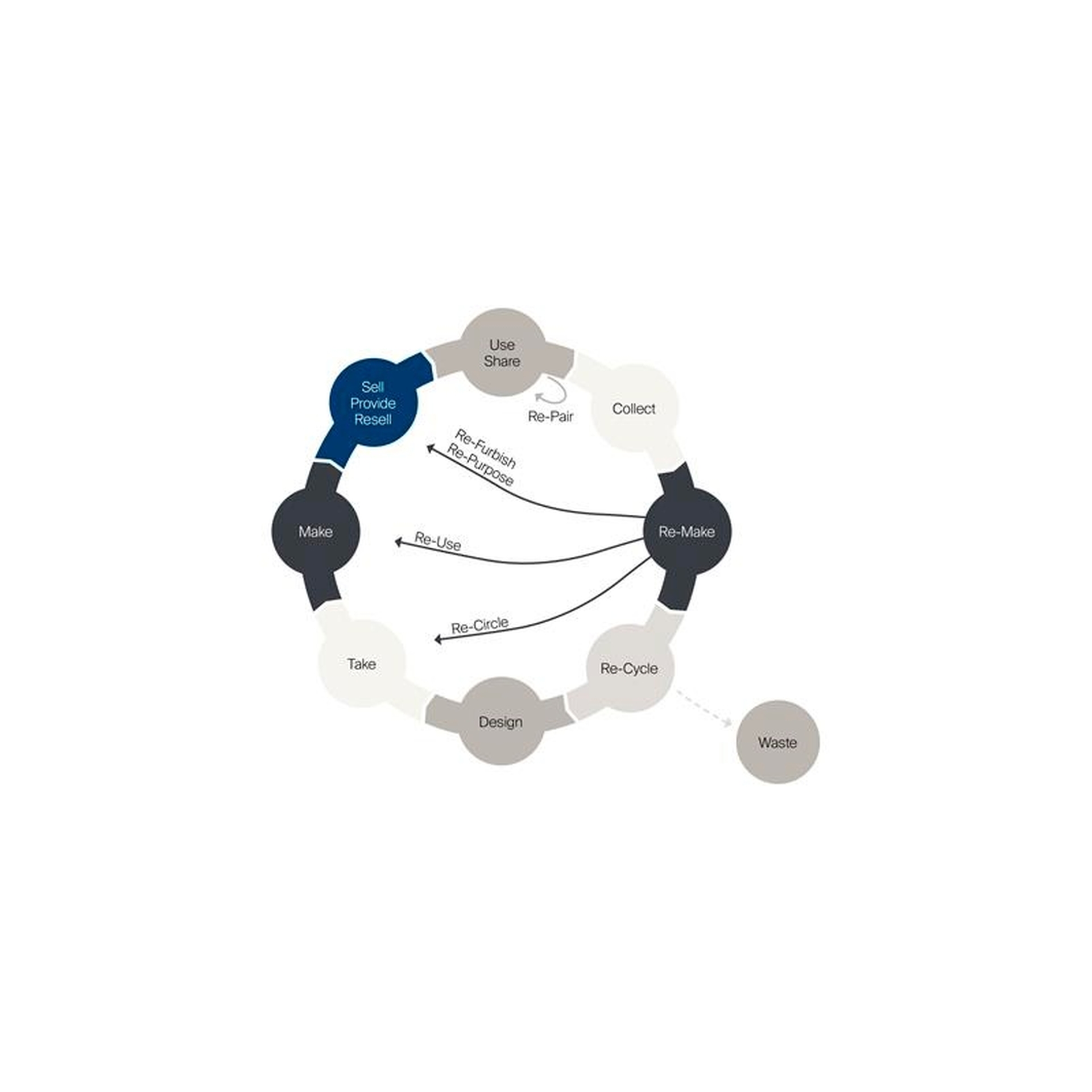

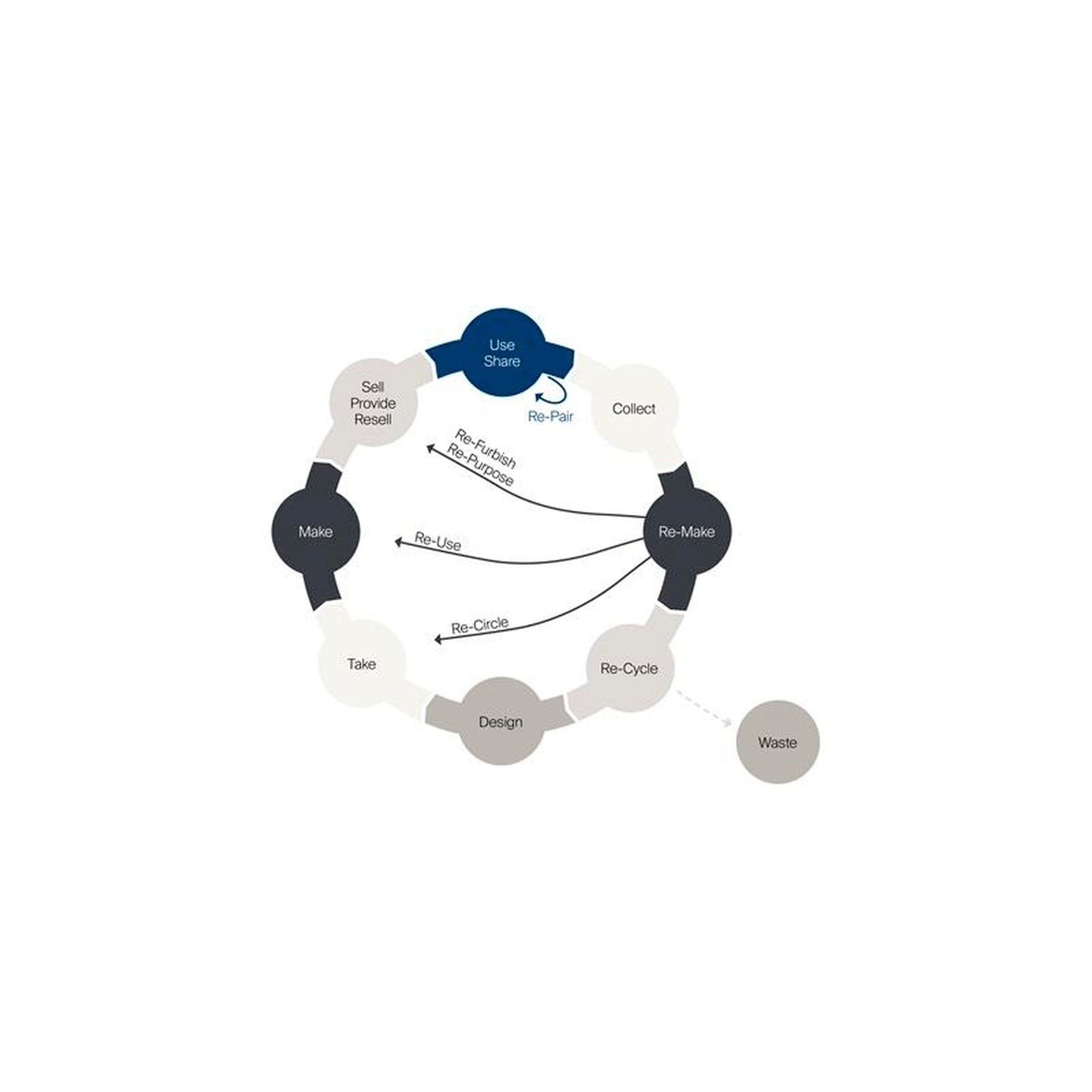

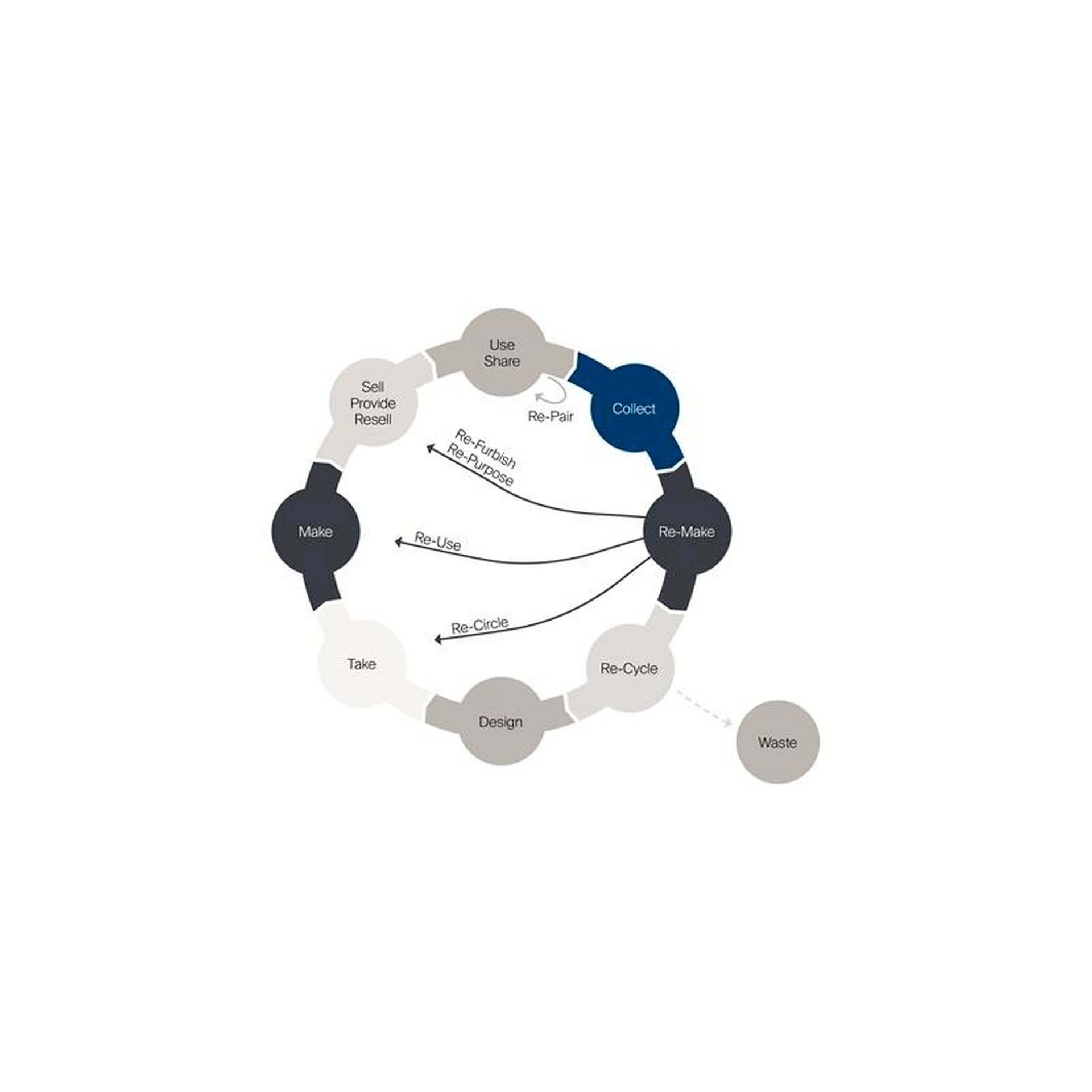

For V-ZUG, the circular economy means taking a holistic view of the entire life cycle of our products. This involves taking responsibility and closing materials cycles. This approach is only possible with good partnerships along the entire value chain. It opens up new opportunities in collaboration with our suppliers, the recycling industry and other partners. The process begins in the development phase, or more precisely in the design phase. This is where we lay the foundation for the future sustainability of our appliances: the selection of resources, use of materials and aspects such as durability, repairability, quality and energy efficiency have always been important. However, the newly defined “Design to Circularity Principles” go one step further, such as with “enabling easy disassembly”, “reusing parts” or “modular design”.

Production and marketing play an equally crucial role: how do we manufacture our products? How do they enter the market successfully? With the Product-as-a-service business model, for example, we no longer sell the appliances, but instead offer them for use and take full responsibility for the entire life cycle of the product. As a large part of the ecological footprint is created during the use phase, we rely on durable equipment and a strong service network. This enables repairs and in turn, extends the service life of our products. We are also working on continuously improving the energy efficiency of our appliances and offering comprehensive functions for ecological use. At the end of the life cycle, there are questions: what happens to worn-out appliances? How can we recover and reuse materials? Our aim is to keep resources in circulation for as long as possible – for a more sustainable future.

You can find out more about V-ZUG’s vision of “Closing the Circle 2040” here.

“Recycling is a good starting point, but we believe circular economy can take things further, because it keeps resources in the loop for as long as possible and at the highest possible value”. - Marcel Niederberger, Head of Sustainability