Cosimo Bizzarri (CB): Your three companies come from very different sectors: home appliances, sanitary ware, knives and accessories. What brings you here together today?

Martin Baumüller (MB): Looking at our three companies, the first thing one notices is they are all iconic brands from Switzerland, with a strong legacy. V-ZUG is 112 years old. Victorinox is 141. Geberit has just turned 150. So we have a long history in common.

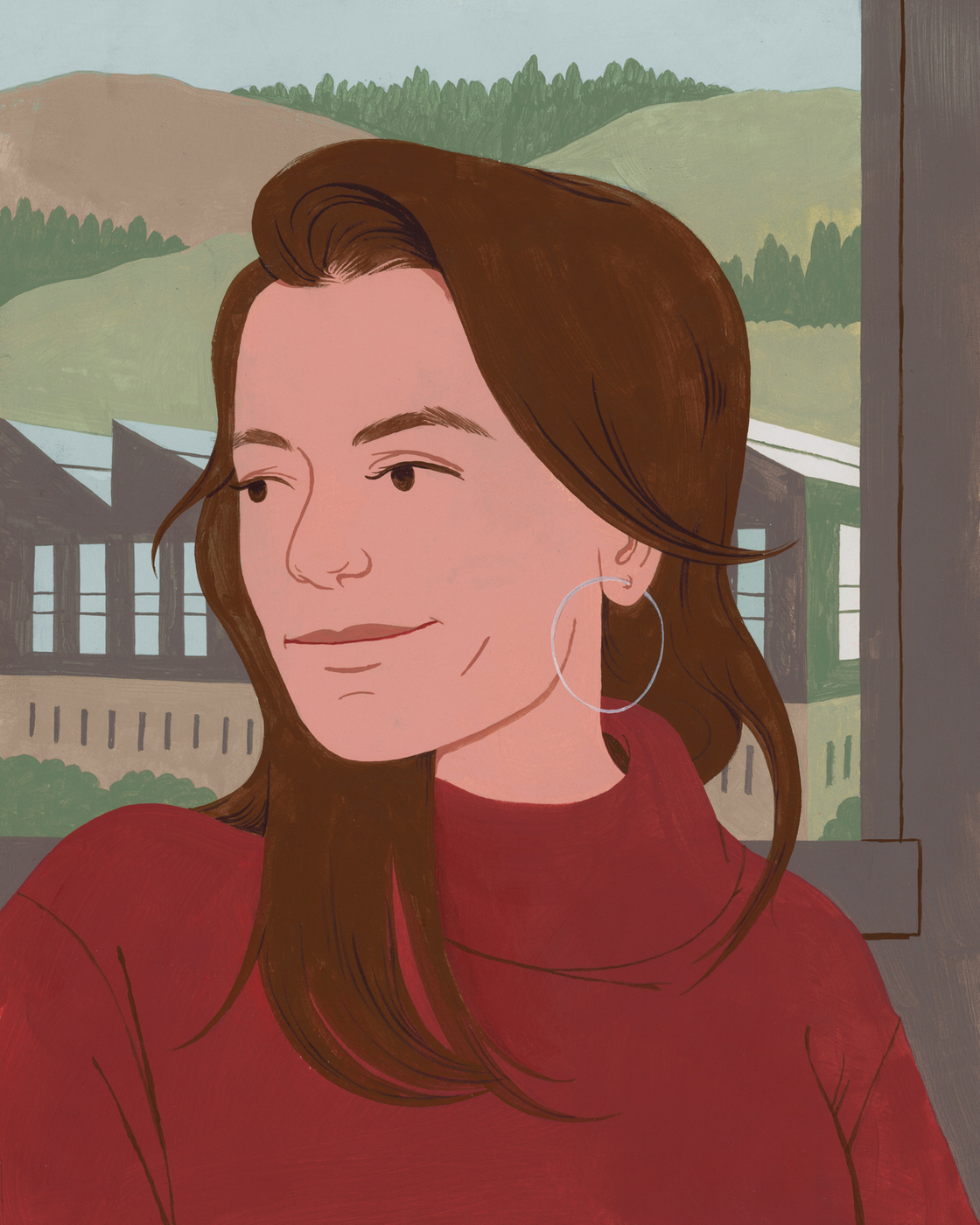

Yvonne Fischer (YF): Also, our three companies focus on quality, precision and a mix of heritage and innovation. So I see a lot of common threads, even if the industries are very different.

Nathalie Noël (NN): Innovation is also something that defines our three companies. What keeps us motivated is the fact that we are constantly in the search for customer-relevant innovation. Swiss people like things straightforward and clear, so another aspect that all our products have in common is that they are always very intuitive.

CB: What is special about the company you work for?

NN: I joined V-ZUG because of its sustainability agenda, which is not driven by laws or regulations, but rather by the company’s ethos. They’ve engaged in visionary projects such as building a multi-energy hub and a vertical factory at their headquarters, and making sure that spare parts for their appliances would be available for at least 15 years. I fell in love with their mission.

MB: I think what makes Geberit special is a strong dedication shared by the 11,000 people that work for the company. It’s a passion for innovation, continuous improvement, making products and customers’ lives better. There’s a very genuine drive within the company, coupled with experience and know how.

YF: This is very similar to how I feel at Victorinox. What surprised me the most since joining the company is that people are truly at its core: employees, suppliers, customers. You feel and breathe the values, day in and day out.

CB: And what about products? Is there a specific product that you think represents your company?

YF: Well, it’s still the classic… There is no way around it: the Swiss Army Knife™. Our founder was a knife maker and a visionary. He built the product so that it could be multi-functional and high-quality. He did a lot of prototyping and feedback sessions from people, asking them how the knife felt, how it sounded and so on, a sort of user-centric process that is super relevant today. In the past, the Swiss Army Knife™ was a portable tool for soldiers, who used it to open cans or cut something apart. Today, most of our customers look very different from those soldiers, but we still pay close attention to them to innovate the product. What is their day like? What are their challenges? Could we add a function to help them?

NN: For V-ZUG, the most iconic product is the CombiSteamer, which combines an oven and a steamer. We worked extremely close with Switzerland’s best chefs to really nail a perfect product that could redefine new cooking habits in the kitchen. I think that the CombiSteamer helped to define the company’s innovation path and a technology that can now be applied to other successful products such as washing machines or dishwashers.

MB: Ours is the cistern, which is basically the tank for the toilet flush. It is the first product that the company brought to market in the early 20th century. Back then, it was a wooden box mounted on the wall. Our founder invented it to improve sanitary hygiene, since his three daughters had died of diphtheria. Later, the cistern was concealed inside the wall—the visible part is the push plate with the two buttons that people use to flush the toilet. Today, in combination with a ceramic toilet bowl, the concealed cistern is still Geberit’s blockbuster product. It’s funny: people send me pictures of it from around the world. It’s a piece of Swissness that people recognise.

CB: Talking about Swissness, your companies have another aspect in common. A strong link with your local territory, and ongoing investment in it. Why is that? And does it come at a cost?

NN: Most of our industry has moved production abroad. V-ZUG made the choice of retaining its production not only in Switzerland, but in Zug—the heart of the company’s history. And it’s not just production. Most key functions within the company are at our Zug headquarters, situated just metres from each other, instead of being spread around the world.

YF: Victorinox has a similar mindset. Everything has to be as near as possible, so logistics can be efficient and the quality can be controlled throughout the manufacturing process. In the past few years, we have built a brand-new Distribution Center in Seewen, near our headquarters.

NN: Producing high quality products in such a location positions us in a segment where customers are willing to pay for premium. But it also allows us to have highly skilled people performing amazing work inside our factories. Take the PowerSteam. Because of its technological complexity, you would probably think its production is highly automated. But in reality, it’s a product that requires a lot of craftsmanship. Today, we have only twelve hands in the company that can put that product together. It’s like making a Swiss watch.