The circular economy only works as a collective effort. It is created when all stakeholders along the value chain take responsibility. And it is founded on shared values, a common creative drive, and transparent communication between everyone involved. At V-ZUG, we consider the circular economy throughout the life cycle of our household appliances. We work within a broad network of partners and put circular principles into practice step by step. Right from the start, we select materials and components carefully. Together with our suppliers, we develop components further, focusing on quality, durability and energy efficiency. While they are in use, service and repair packages ensure that our appliances remain viable for as long as possible. At the end of their life cycle, specialist waste disposal service providers ensure that the equipment is recycled properly. The better the materials are sorted for processing, the more easily they can be reused. Just how well this works is demonstrated by our current refrigerator range. Together with the dismantling company SuperDrecksKëscht® (SDK), we completely close the material cycle of our plastic cover (the lid of the inner body). The component, which weighs around 1 kg, will in future be made from 100% recycled ABS plastic obtained from scrap refrigerators.

A functioning circular economy emerges when everyone along the value chain takes responsibility. Together with long‑standing partners, V‑ZUG closes material loops step by step—showing how collaboration, quality and innovation enable durable products and meaningful reuse.

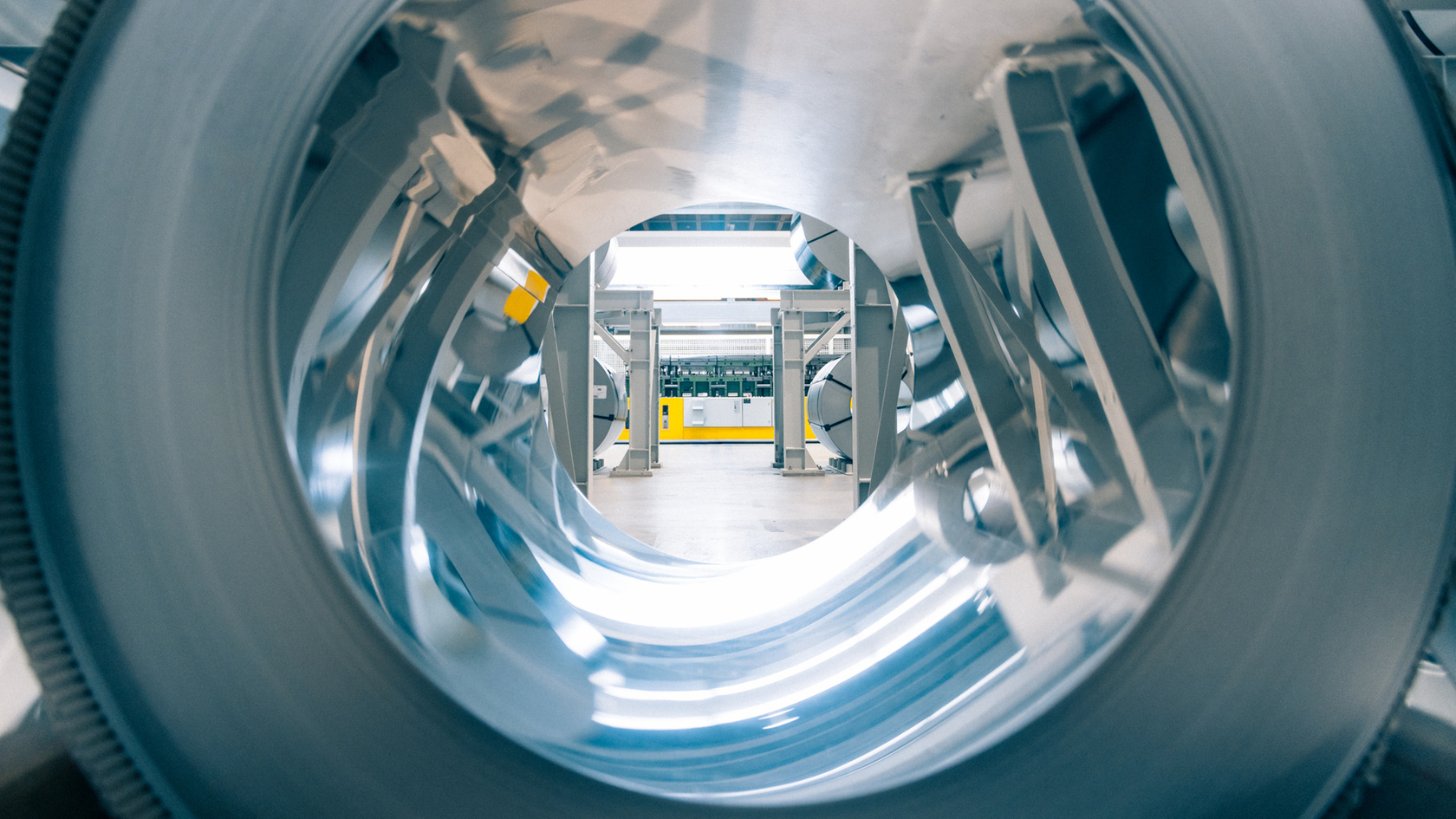

Our presence in Switzerland goes beyond Zug. We are proud to have opened 2022 the most modern European cooling factory in Sulgen. Both products and processes are committed to being as sustainable as possible.

The cycle begins with the manufacture of the refrigerators in our plant in Sulgen. After many years of use in Swiss households, they end up being sent for recycling. At its Rheinfelden site, recycling service provider SDK processes the equipment into individual material streams. A separate ABS fraction then goes to SEG Umwelt Service, a sister company of SDK, which combines it with ABS plastic from other European dismantling facilities and processes the material into high-quality recycling granulate. This is where Stüdli Plast AG, an existing, long-standing Swiss supplier to V-ZUG, comes in. Working in close cooperation with the injection moulding manufacturer, we subjected the recycling granulate to extensive quality tests and approved it for component production. From 2026, our Sulgen refrigerator plant will gradually integrate the new lids made from this recycled material into its series production. This project demonstrates what is possible when everyone involved collaborates. The reuse of materials reduces the environmental footprint of our products. And it proves that circular solutions can be economically viable when scaled correctly.