With the rise of Artificial Intelligence, automation has come to pervade many aspects of our everyday lives: from the way we shop, to the way we learn, communicate and get around. The latest technologies are also having a huge impact on how goods are produced, stored and dispatched: industrial automation improves safety, simplifies routine tasks and allows for higher productivity levels and more efficient logistics. Some people think that highly robotised factories might one day be able to do without humans. However, the opposite is true: the more complex the automated system, the more crucial the human contribution, because you need outstanding people to design, operate and complement expert machines.

Automation is changing the way V-ZUG manufactures its products, but it is people who still make the difference.

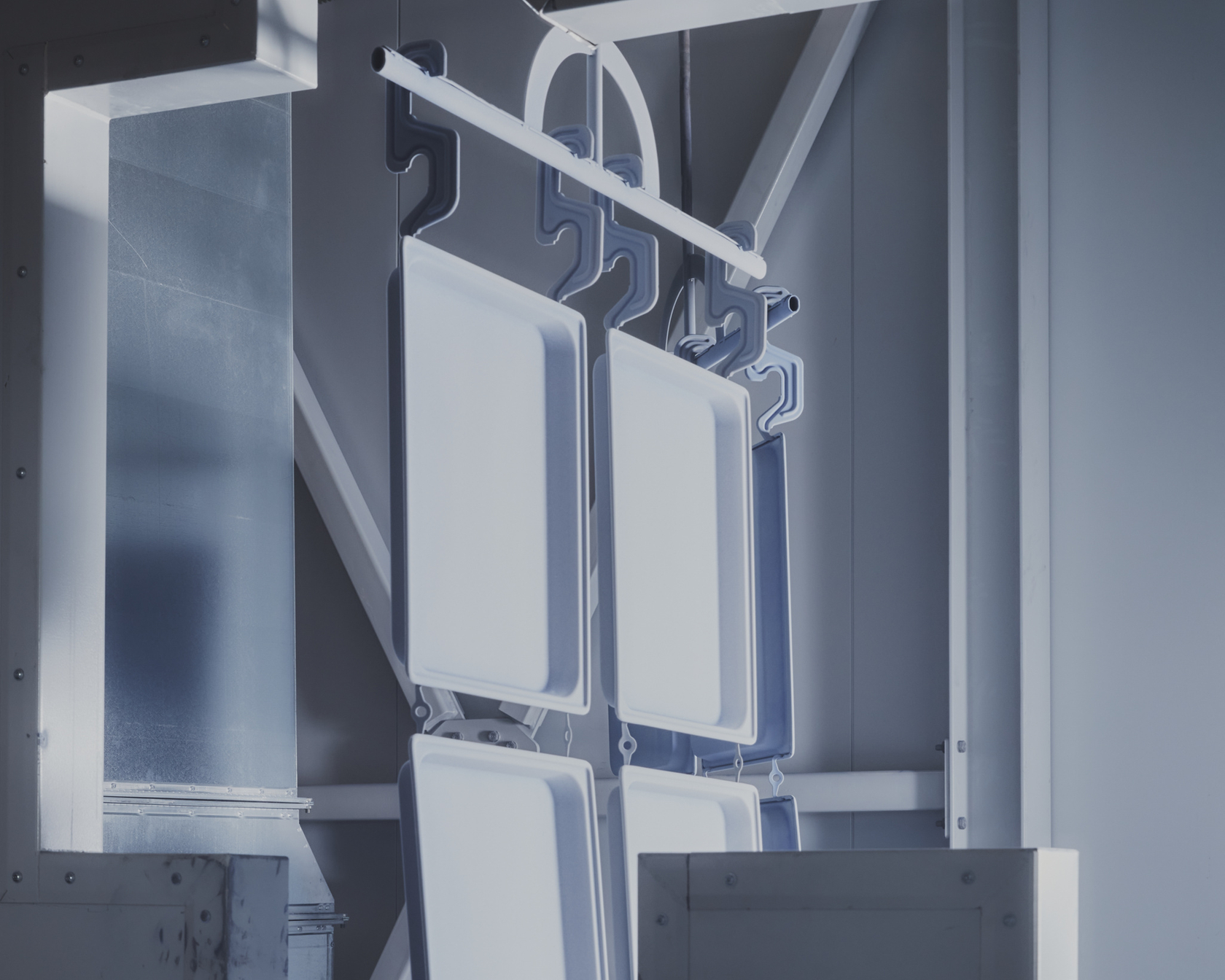

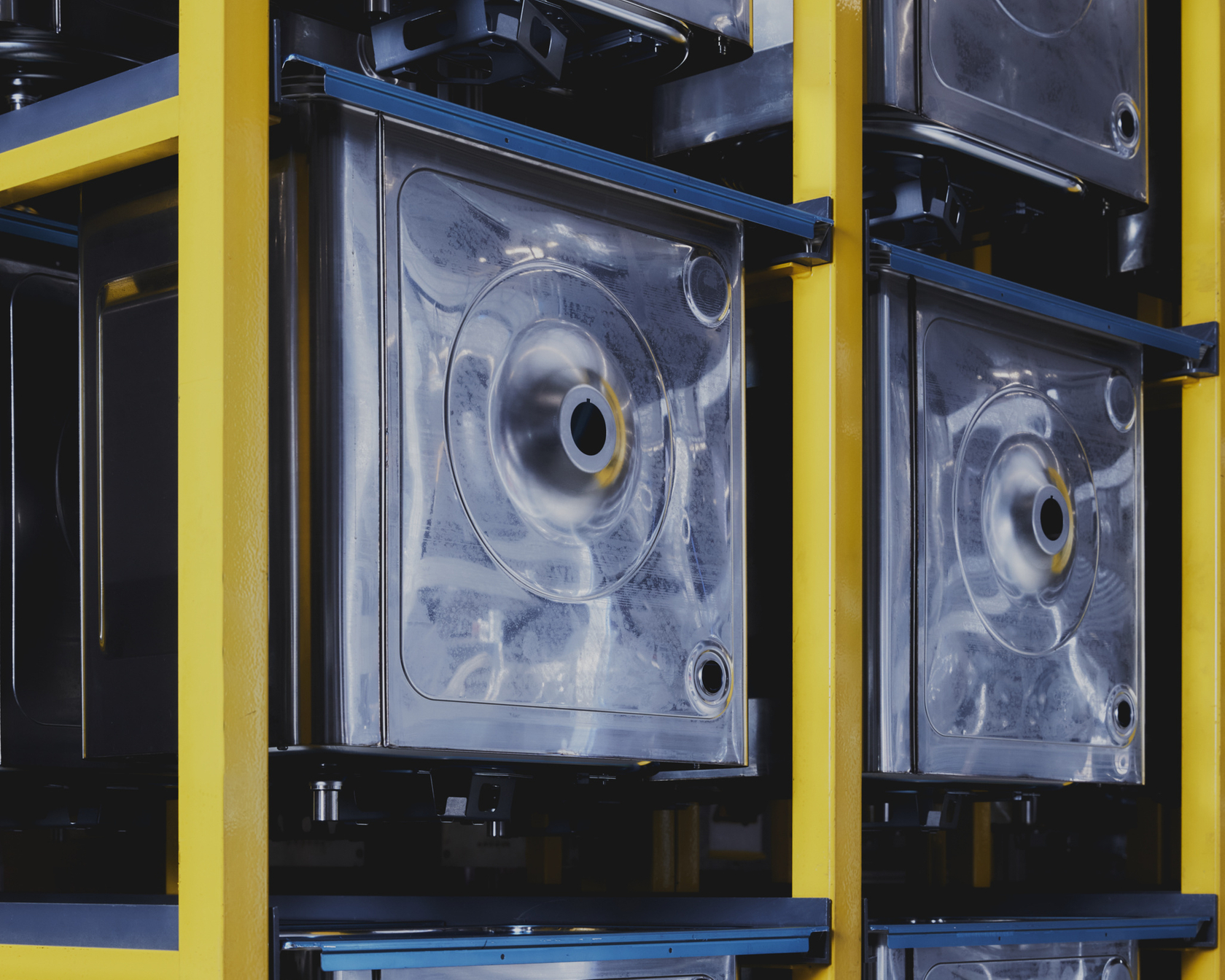

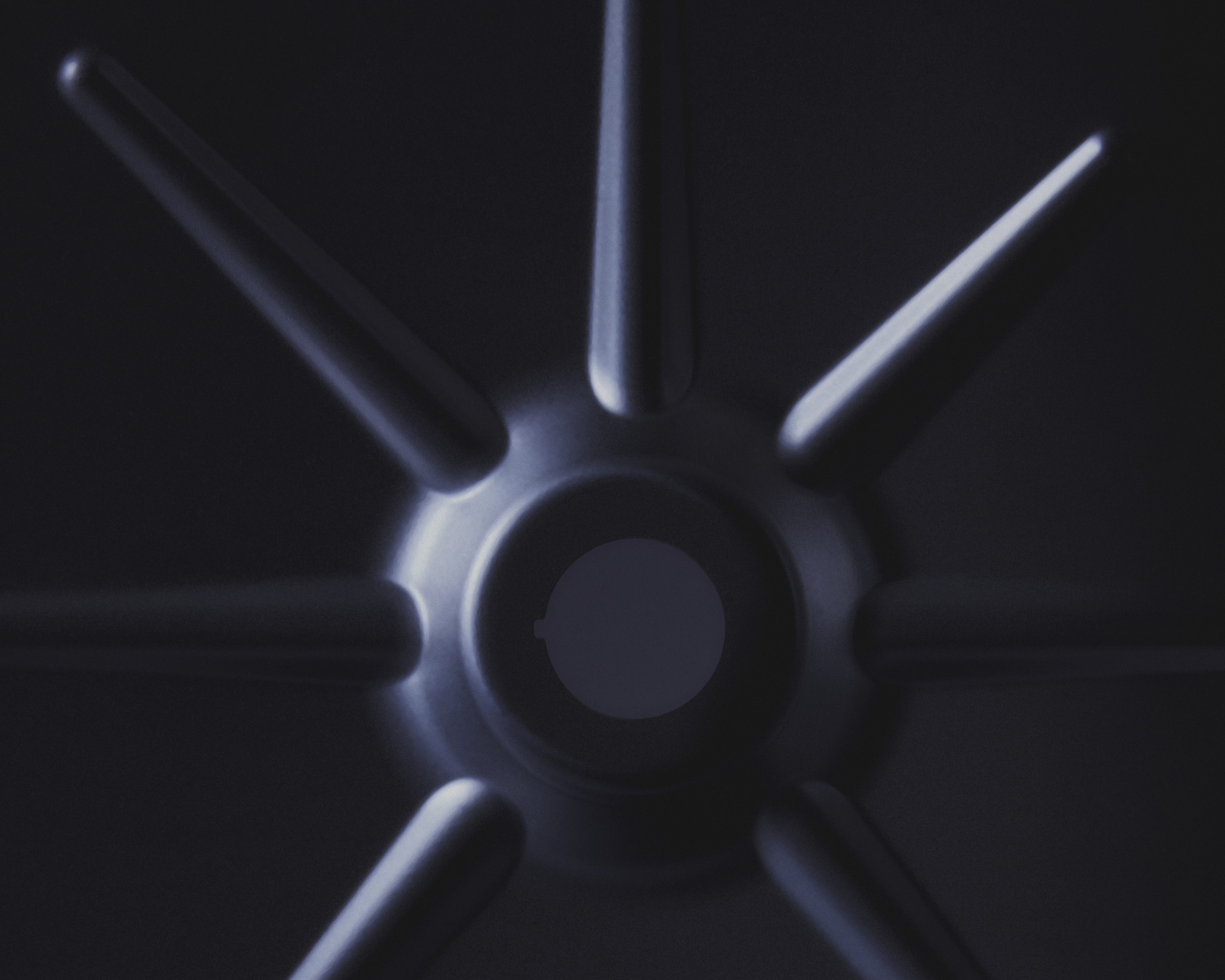

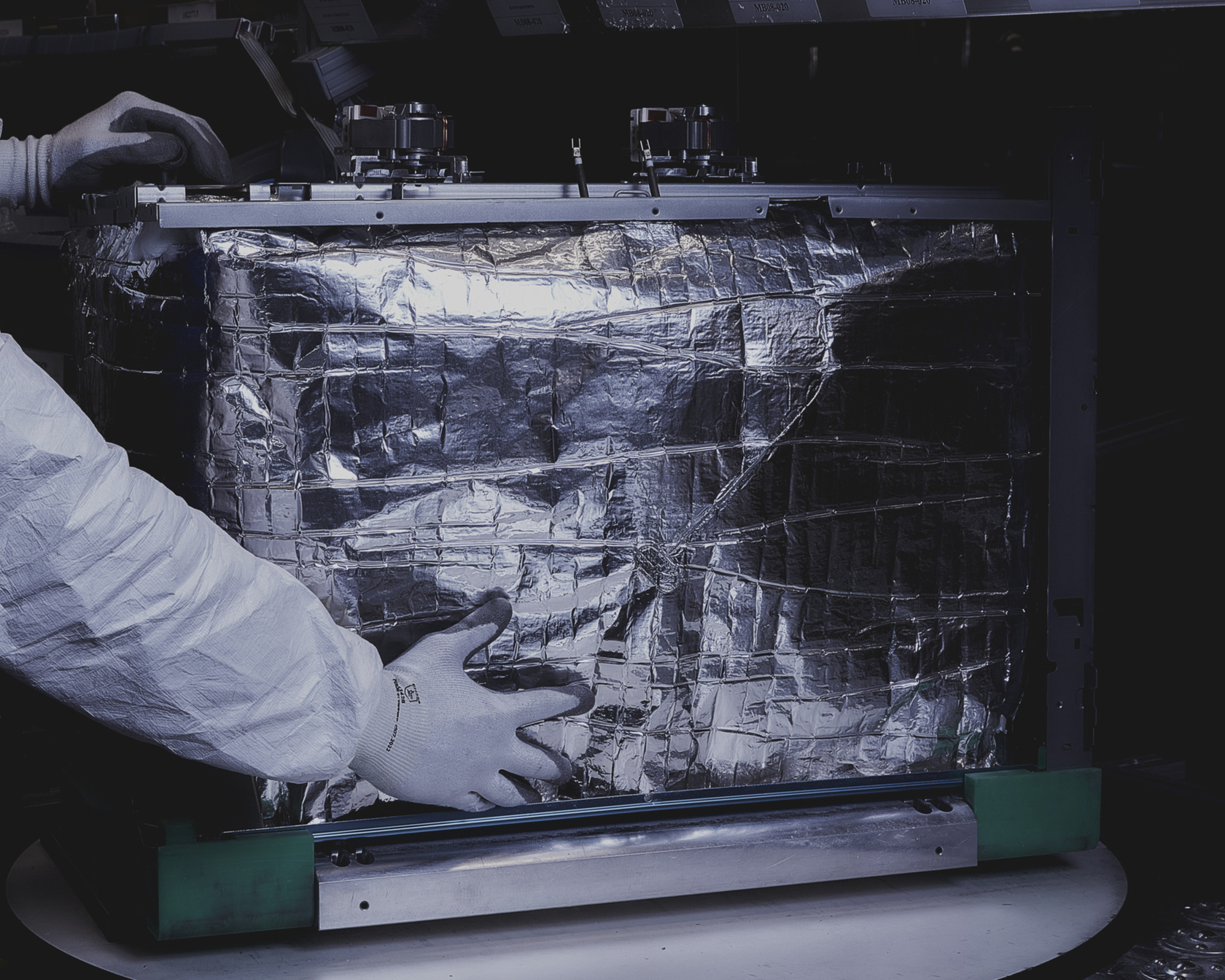

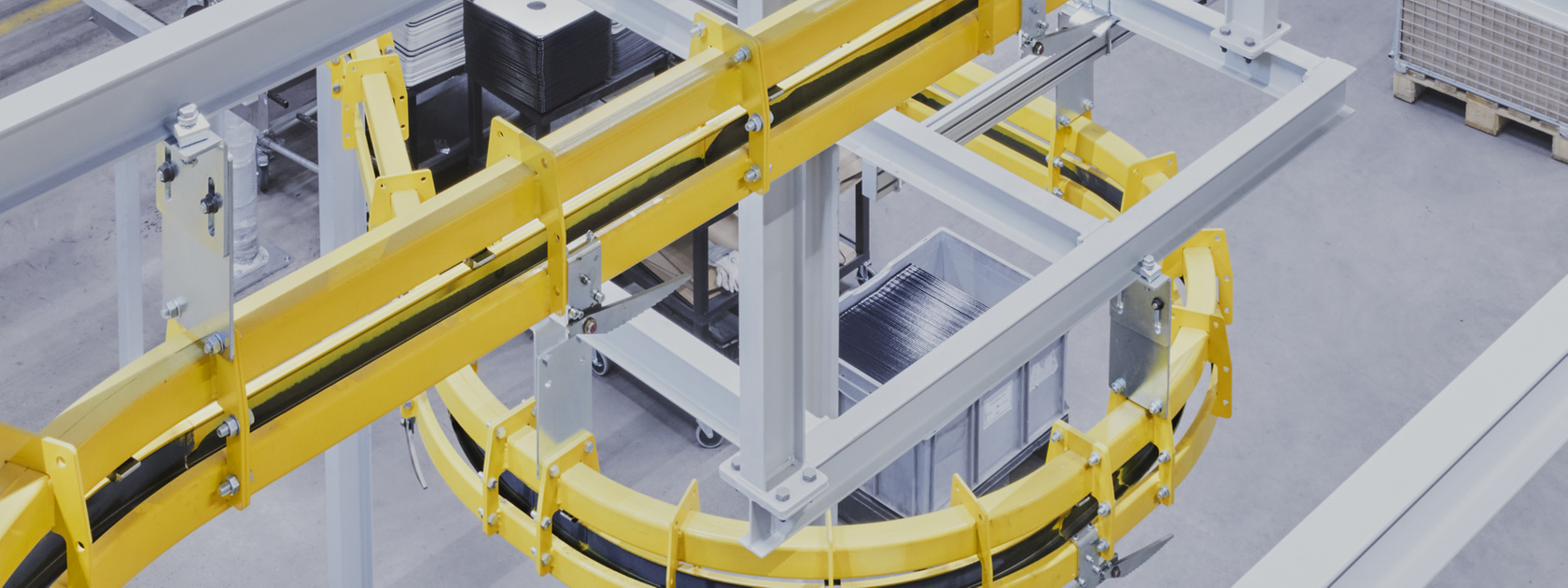

This is exactly what is happening at V-ZUG. The company is currently restructuring its facilities in order to streamline manufacturing and logistic processes across multiple floors. By the end of 2025, the production capacity is expected to double, while the factory floor surface will shrink by 60%. While such a vertical factory relies on state-of-the-art automation, humans are still its most important asset. They are not only in charge of designing, maintaining and sometimes building the amazing machines that contribute to making almost 1300 first-class home appliances every day, they also perform metal work that requires a level of accuracy only a person can achieve. And not any person. Factory workers are both thoroughly trained and required to constantly rotate tasks, an approach that keeps them engaged and ultimately increases the quality of their work. Such a highly trained, efficient and flexible local workforce makes V-ZUG a one-of-a-kind company, not only in Switzerland but in the whole of Europe. It is the best guarantee for customers that the product that ends up in their house has been made with competence and love.