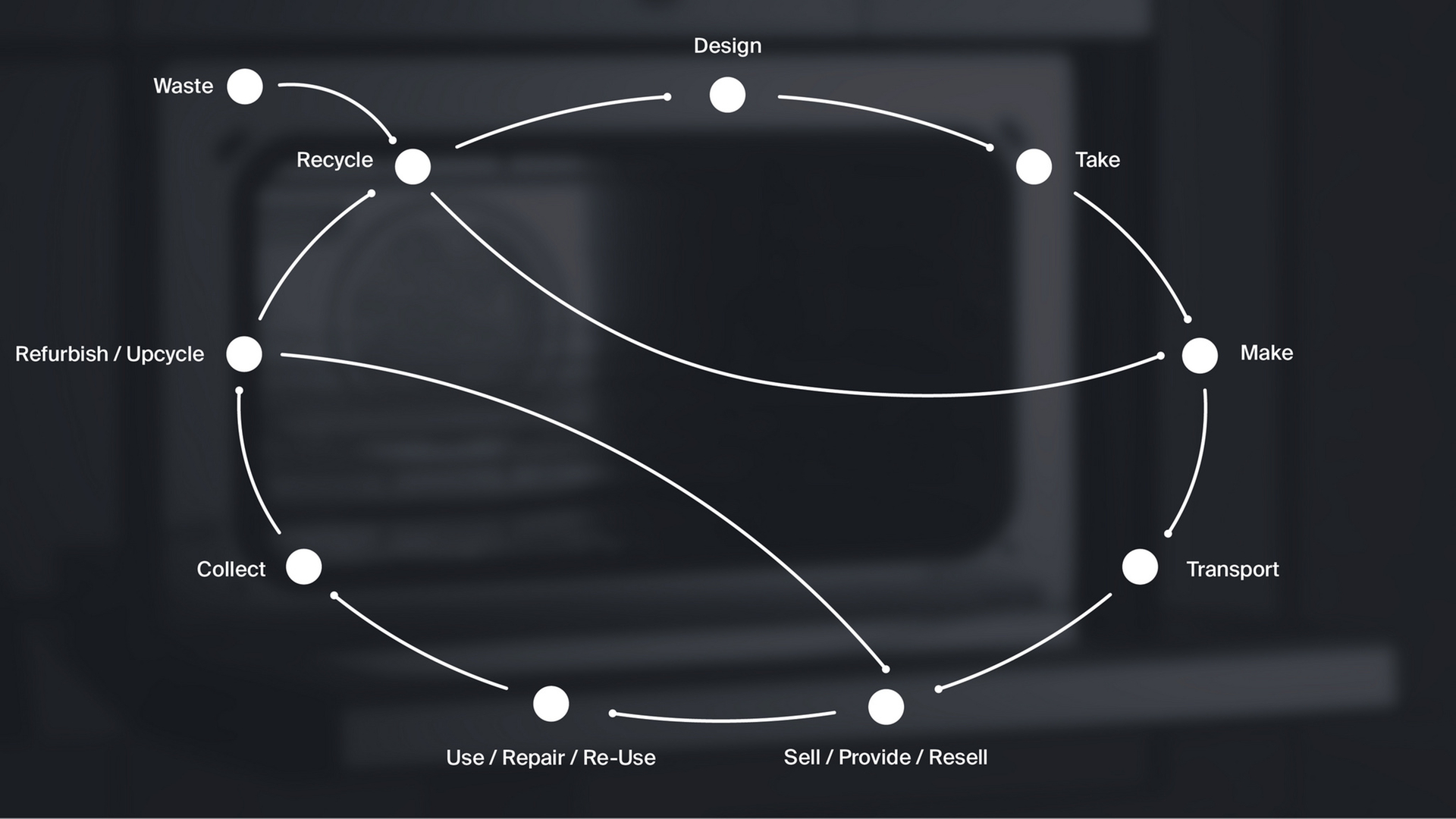

Circular economy

For us, a sustainable product begins with its development. It is at this early stage that we can have the most influence on its ‘lifelong’ sustainability. We focus on elements including the durability and repairability of the appliances, low energy and water consumption in use, material choice and a modular design to enhance circularity.